Custom Engineering Projects

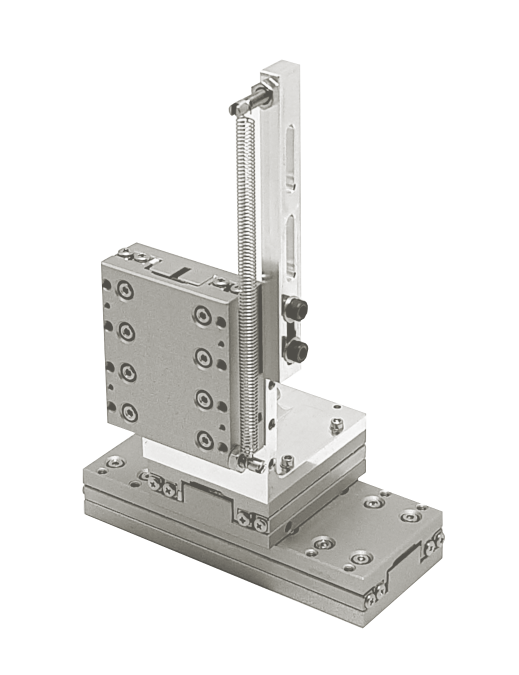

Complex motion systems. Turning ideas into reality.

Many of our customers have specific requirements that are hard to fulfilll with standard equipment alone. We therefore created the Xeryon Custom Engineering Team in 2015, with one goal: to realise custom engineering projects. The team consists of senior mechanical and automation engineers with a focus on precision engineering. The range of the custom projects goes from small adjustments of existing products to full scale engineering projects of automation subsystems and mechatronics projects. Some examples of projects we've been working on:

Small customisations:

- Extra mounting points

- Additional travel range

- UHV adaptations (10-9Torr)

- Aperture holes

- Custom sample holders

- Very long cable lengths (>100 m)

- Extreme magnetic fields adaptations (>1 T)

- Mass compensation systems

- Custom communication protocols

Full engineering projects:

- Precision pick & place setup

- Integration within existing machine design

- Lens control systems

- Beam control systems

- In-orbit stability systems

- Custom shutter development

We understand that a complex project needs to go through multiple validation steps. Xeryon supports you in every step of the development process.

- Conceptual engineering

- Proof-of-concept

- Detailed design

- Prototyping

- Series production

- Quality testing

- Final product validation

- User manuals

- Technical intervention planning

Contact us to discuss your small or more complex custom engineering project. The Xeryon Customer Engineering Team is ready to turn your project into a success.