Linear actuators: Stepper motor vs piezo motor driven

Reading time: 5 min

Whether you're designing the next breakthrough medical device, a new laser device or automating a precise semicon manufacturing process, choosing the right linear actuator can make or break your project. Dive into the differences between Stepper Motor and Piezo Motor linear actuators to find out which suits your needs best.

Stepper Motor Linear Actuators

How does it work

A stepper motor is an electro motor that converts electrical pulses into discrete mechanical movements, known as "steps." Each time current is delivered to a phase, the motor rotates a specific step. The size of this step is determined by the motor's design. A microcontroller or another control device sends electrical pulses to the motor. The rotation of the motor is converted into a linear motion by use of a lead screw, a rotating nut or a rack and pinion combination.

Advantages:

- Cost-Effective: Stepper motors actuators are generally less expensive, making them a great choice for budget-sensitive projects.

- Simplicity: Easily controlled and widely understood, stepper motors actuators offer a straightforward approach to movement.

- High force: Provides a strong force, especially at lower speeds, which can be essential in some applications.

Limitations:

- Size and Weight: Typically bulkier and heavier compared to piezo actuators. Stepper motors have a miniaturization limit because at a certain size the magnetic flux density becomes too small to generate any torque.

- Limited Resolution: Even with microstepping, there's a limit to the precision of movement.

- Decreasing precision: As the gears or the lead screws wear off, out the precision of the actuators decreases

- Heat Generation: They can get hot during operation, which might require additional cooling measures.

Piezo Motor Linear Actuators

How does it work?

There are three main categories of piezo motors actuators:

- Stick-slip piezo actuators (sometimes called “Inertia motors actuators”)

A back-and-fourth system that slips in one direction but slips in the other direction, resulting in a net linear motion - Walking piezo actuators

Multiple piezoelectric elements function in a coordinated manner, achieving continuous walking motion. - Ultrasonic piezo motor actuators

By operating the piezo element at its resonant frequency (typically > 100kHz), it's possible to achieve amplified motion, higher speeds and vibrationless motion.

Advantages:

- Precision: Piezo actuators offer micrometer or even nanometer precision, making them perfect for high-resolution applications. However, piezo actuators are also used in conditions that do not require extreme precision, but do need to be as compact as possible.In contrast with stepper actuators, the precision level stays the same throughout the lifetime of the piezo actuator, as most versions do not contain any gears or lead screws.

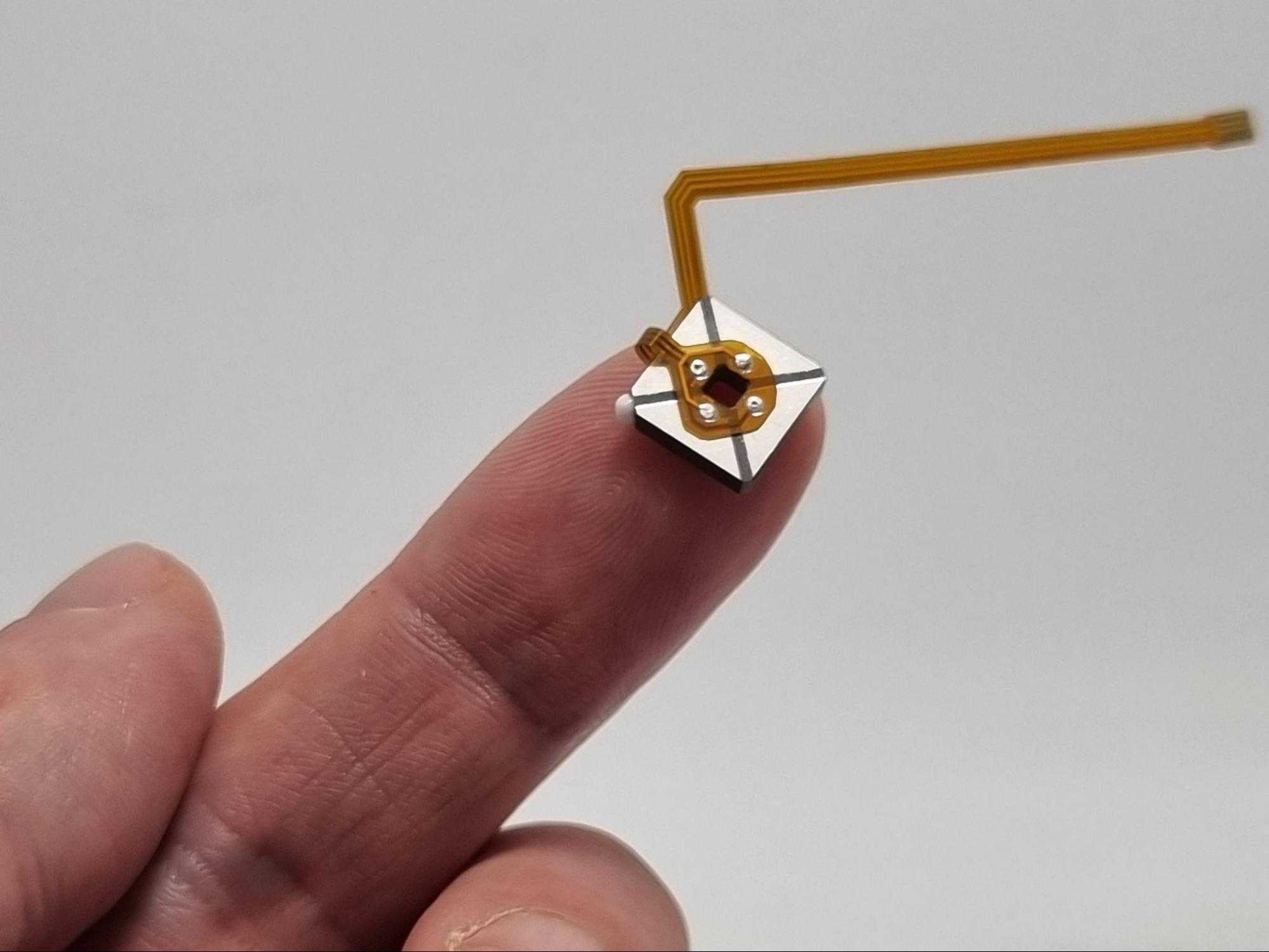

- Compactness: Significantly smaller and lighter than stepper motor actuators. Piezo actuators are the smallest industrial motor technology.

- No Magnetic Field: Operate without producing magnetic fields and do not contain any ferrous components, which can be crucial in sensitive environments like MRI machines or scientific labs.

- Energy Efficient: Consumes power only when moving, and generates less heat.

Limitations:

- Price: Generally more expensive due to the materials and precision engineering involved.

- Drive: Requires specialized drivers.

- Force Limitations: While precise, they might not offer as much force as some stepper motors. Typically you can expect driving forces between 1N and 10N

- Lifetime: Stick-slip and Walking piezo actuators have very short lifetimes, making them unusable for most medical or industrial applications. Ultrasonic piezo actuators have a lifetime that is comparable to stepper motors (> 1000 km and > 10 million cycles).

Which One's Right for You?

Stepper Motor Actuators are your best bet if:

- You're on a tight budget.

- You need high torque, especially at low speeds.

- You do not need to go as compact as possible

Piezo Motor Actuators shine when:

- Precision is required.

- Space and weight are priority

- You need an actuator that doesn't produce magnetic fields.

Ready to Make a Choice?

Whether you're leaning towards the robustness of the stepper motor or the precision of the piezo motor, we have a range of products to suit your needs. Get in touch with our team of experts to discuss your requirements and let us help you make an informed decision.