What is the lifetime of a piezo motor?

Reading time: 3 min

Piezo stack

When evaluating the lifetime expectancies of piezo motion systems, a distinction needs to be made between piezo-stacks and other piezo-systems. A piezo stack is, as the name suggests, a stack of piezo-elements. When a voltage is applied on each element, they contract or expand a little, resulting in a movement of the tip of the stack. The lifetime of individual piezo-elements is virtually unlimited and the same can be said for a piezo-stack. The big disadvantage of a piezo stack is the limited travel range of the system. A maximum stroke of 100 µm is feasible but only if high voltages are being applied as the deformation of the piezo element is directly proportional to the applied voltage.

Amplified piezo stack

If a piezo-stack is integrated into a piezo-amplifier the stroke length can be increased up to 1mm. The amplifier is basically a simple leverage system that adds travel range at the expense of loss of force. The concept is comparable to how a lifting jack from a car works. Again, these systems have a very long lifetime expectancy, as all components rely on the elasticity of metals only, rather than on force transmission components like gears or sliders.

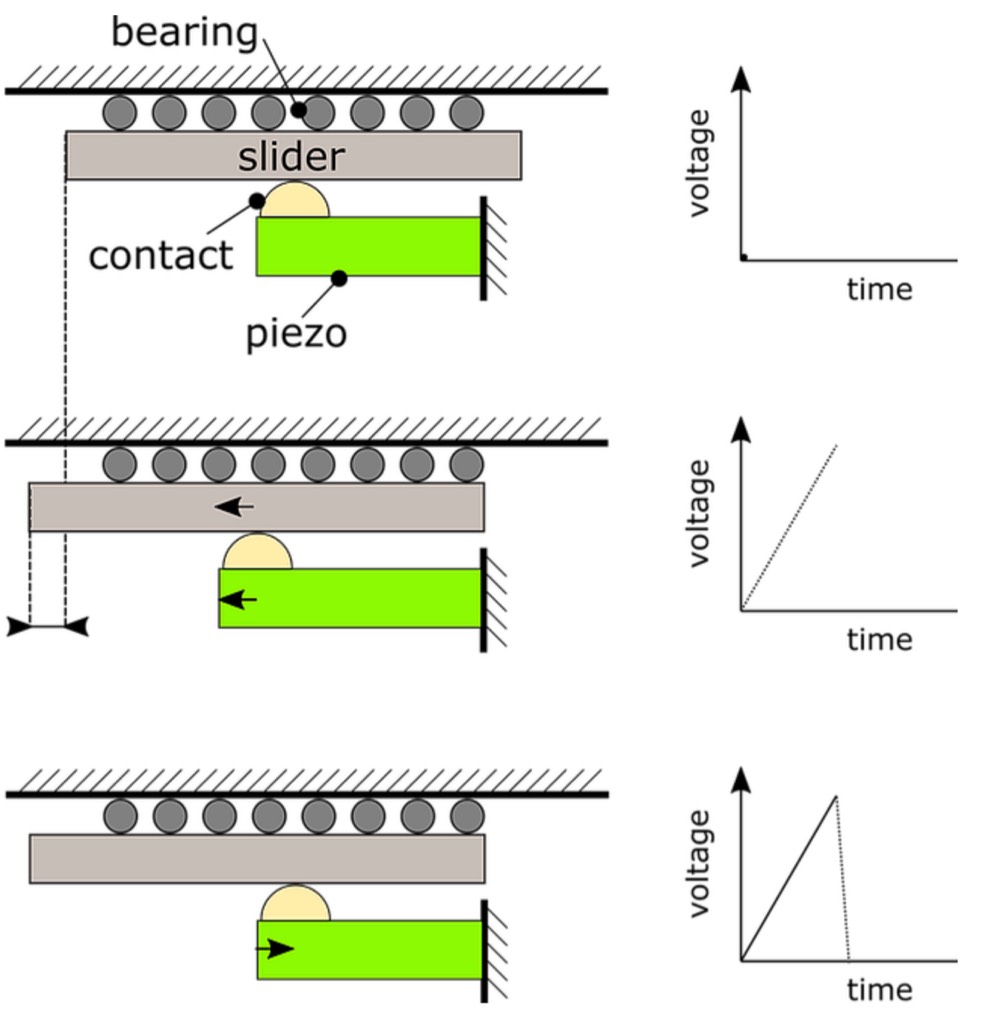

Stick-slip piezo motor

Also called “inertia piezo” systems. Typically used in linear and rotation precision stages for scientific research, these systems work by moving a contact point back and forth against a ceramic strip at a very high frequency. By varying the speed, the contact point “sticks” in one direction and “slips” in the other direction, resulting in a net motion. The constant slipping has a huge impact on the lifetime of the piezo-system. To have sufficient moving force, the contact point needs to be pushed firmly against the ceramic strip. But that means that when it slips back to the starting position, there is a lot of wear on the contact point. Lifetimes are typically expressed in kilometers of net motion. In the case of a stick-slip piezo motor a lifetime of 10 - 20 km is to be expected. When used continuously at a speed of 3 mm/s (the stick-slip top speed) this equals to a lifetime of 1 - 2 months.

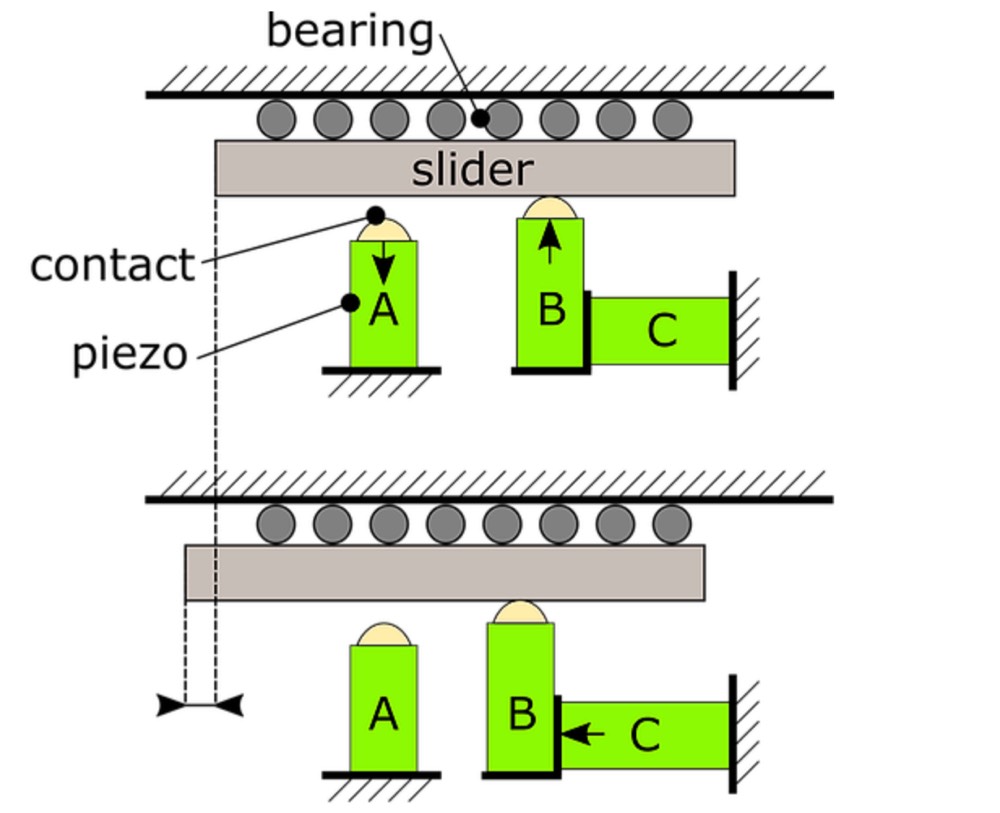

Walking piezo motor

Walking piezo systems, sometimes called piezo-walkers, piezo-legs or piezo steppers, are an alternative to the stick-slip piezo. The contact points don’t slide back over the ceramic strip but first retract before returning to the starting position. The downside of these systems is the slow speed and the complexity of the system: 4 piezo-elements are needed instead of only one. There still is some minor slippage which has some impact on the lifetime, typically reducing it to about 50 - 100 km. If used continuously at a speed of 10 mm/s this equals to 3 - 4 months of use.

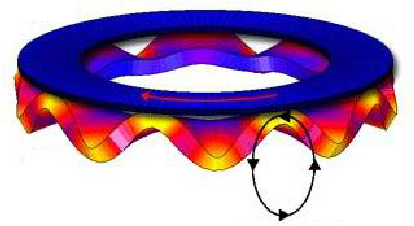

Ultrasonic piezo motor with traveling wave

This specific type of piezo system is based on a (ceramic) ring that vibrates and generates a traveling wave that moves around the ring. Contact points that push against the ring are propelled by the waves in the ring, just like a surfer is being pushed forward by a wave. Because of the large contact surface between the contact points and the ring very little wear takes place. The disadvantage of these systems is that they can only be used for rotary motions as the waves need to be able to continue their journey around the ring. That makes them useless for linear motion. Another drawback is that they are great for very slow speeds but are not suitable for high speed rotations. They have a very good lifetime of 250 million rotations and more.

Ultrasonic piezo motor with standing wave

For this kind of piezo motor a piezo-element pushes against a ceramic strip and makes an “elliptical motion” against the strip, in contrast to the back and forth sliding in a stick-slip system. The high speed elliptical motion allows for an almost contactless return to the starting position, resulting in very good lifetimes and very high travel speeds up to 1000 mm/s. Also a large surface area for the contact point can be used, resulting in great lifetimes. This large contact surface is not possible in stick-slip systems as this contact point has a negative effect on the dynamic behavior of the “stick” and “slip” motion. Xeryon ultrasonic piezo motors have an expected lifetime of 200 to 300 km, about ten times better than stick-slip stages. When operated continuously at a speed of 10 mm/s, the lifetime is 10 - 12 months.