Piezo actuators: applications, types and (dis)advantages

An overview of the three most common types of piezo actuators, their applications, advantages and disadvantages.

Types of piezoelectric actuators

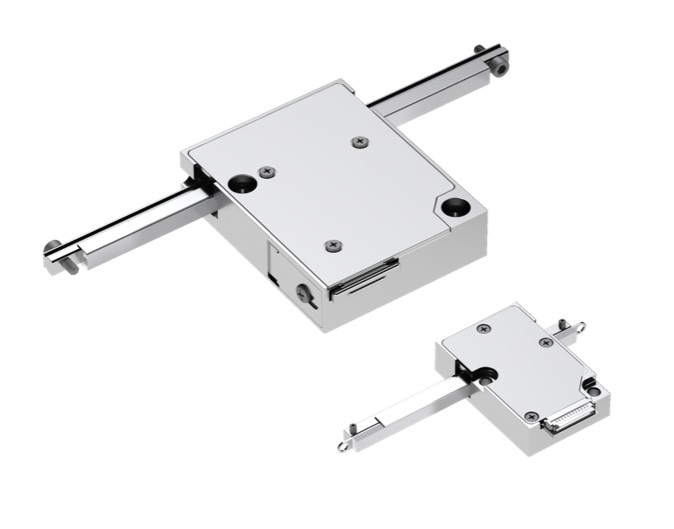

When piezo linear actuators are mentioned, engineers often think of stick-slip piezo actuators or walking (stepping) piezo actuators.

A third type, the ultrasonic piezo actuator, has made a name for itself in recent years as a slightly less precise yet much more versatile and cost-efficient technology. In this article we will describe each of these 3 piezo actuator types, their ideal applications and (dis)advantages.

We also included a comparison table at the bottom of this page, giving an overview of the key features and specifications of each of these linear actuators.

Applications & (dis)advantages

1. Stick-slip piezo actuator (inertia piezo):

Working principle: Stick-slip piezoelectric actuators operate on alternating 'stick' and 'slip' phases. During the 'stick' phase, the piezo is slowly extended, moving the slider with it. In the 'slip' phase, the piezo retracts rapidly, causing the slider to advance due to inertia.

Applications: Stick-slip piezo actuators are suitable for high-precision applications where speed, travel range, noise and costs are not a concern.

Advantages: Compact size, extreme precision.

Disadvantages: Very low speed, short travel range, short lifetime, very high cost, external encoder sometimes needed.

2. Stepping piezo actuator (walking piezo or piezo legs):

Working principle: Stepping or walking piezo actuators consist of multiple piezo actuators working together. Some actuators grip the slider while others move it. This coordinated action allows for controlled stepping motion in a linear direction.

Applications: Stepping piezo actuators are ideal for high-force, precision applications where linear actuator alignment and stability are crucial, despite lower speed.

Advantages: Extreme precision, high force relative for piezo actuators.

Disadvantages: Low speed, short travel range, external encoder needed.

3. Ultrasonic piezo actuator (with standing wave)

Working principle: Utilizes elliptical oscillations of the contact points to generate motion. This advanced method allows for high-speed, precise movement with minimal noise.

Applications: The ultrasonic piezo actuator is perfect for medical, semicon, and laboratory environments where precision, small size, minimal noise and low voltage are essential. Its high speed can also be beneficial in certain applications.

Advantages: Compact size, very high speed, high precision, unlimited travel range, very long lifetime, integrated controller, noiseless operation, relatively low cost, self-locking, low power consumption, low voltage.

Disadvantages: Not suitable for extreme precision.

Comparative overview: Piezo actuator types

| Type | Size | Speed | Force | Resolution | Travel Range | Lifetime | Vibrations/Noise | Power Consumption | Internal Voltage |

|---|---|---|---|---|---|---|---|---|---|

| Stick-Slip Piezo | Compact | 1-20 mm/s | 1-10 N | <1 nm | 1-50 mm | 10-20 km | Noisy | Moderate | >200 V |

| Stepper Piezo | Larger | <10 mm/s | 5-20 N | <1 nm | 1-50 mm | 50-100 km | Noisy | Moderate | >200 V |

| Ultrasonic Piezo | Compact | 1000 mm/s | 1-10 N | 0,3 μm | 1-300 mm | >1000 km | Silent | Low | <48 V |

Conclusion

While each type of piezo actuator has its own advantages, disadvantages and ideal applications, the ultrasonic piezo actuator stands out for its performance and versatility. Its long travel range, lifetime, efficiency, speed and safety put it into a different category of piezo linear actuators. When ultra-high precision is a requirement and other factors are less important, stick-slip or walking piezo actuators may be more beneficial.

Take a look at our XLA ultrasonic piezo actuator or learn all about piezo technology here.