Voice coil actuators vs Linear Motors vs Ultrasonic piezo actuators

Voice coil actuators vs linear motors vs ultrasonic piezo actuators: A comparison of three types of commonly used compact linear actuators.

Types of high-precision actuators

When mentioning compact high-precision, high-speed linear actuators, the types that typically come to mind are voice coil actuators and linear motors. Ultrasonic piezo actuators, on the other hand, are a newer and relatively unknown type.

In this article we will compare these 3 types of linear actuators, addressing their applications and (dis)advantages. Since linear motors are typically larger than voice coil and ultrasonic piezo actuators, this article focuses only on compact linear motors.

Below you will also find a comparative overview which summarizes their typical specifications.

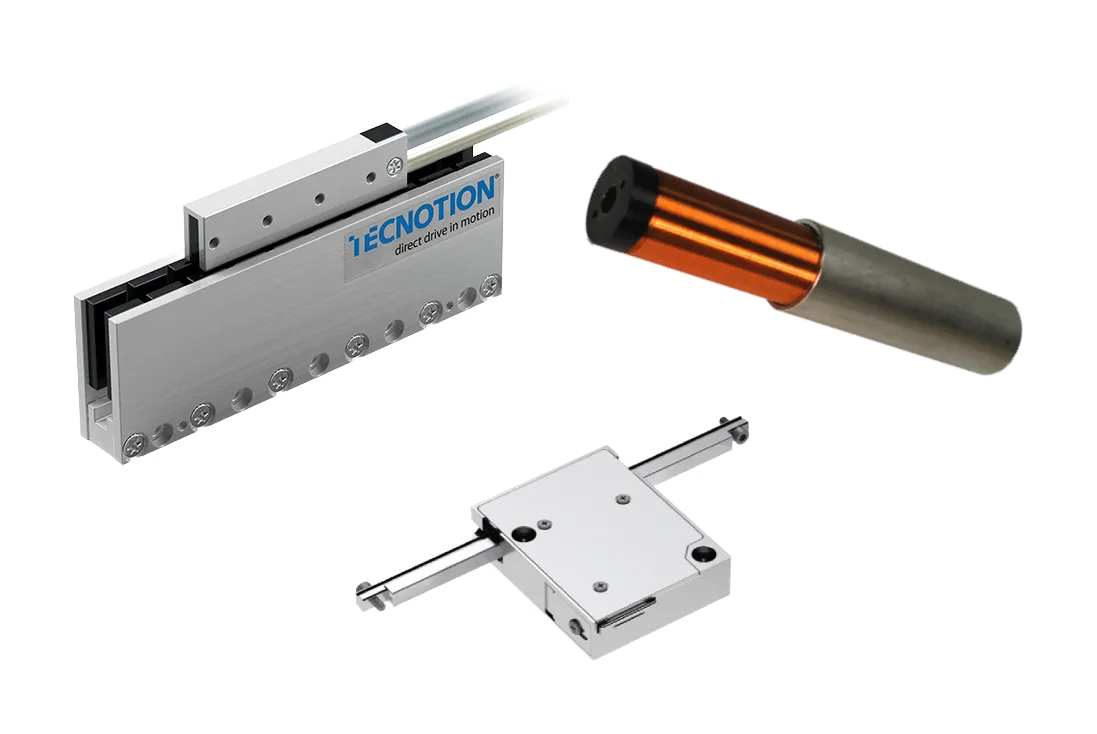

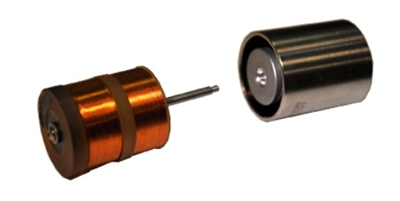

Voice coil actuators

Working principle: Voice coil actuators generate linear motion using the Lorentz force principle. They consist of a coil placed within a magnetic field (typically from a permanent magnet). When electric current flows through the coil, it interacts with the magnetic field, producing a force that moves the coil linearly.

Applications: Voice coil actuators are used mainly in applications that need small, precise movements. They are commonly found in medical and scientific equipment for fine adjustments, and in cameras and telescopes for focusing. Their ability to move smoothly and respond quickly makes them useful in these specific areas.

Advantages: Relatively small, high speed, high precision, simple working principle.

Disadvantages: Very short travel range, low force output compared to linear motors, expensive, heat generation with continuous use.

Linear motors

Working principle: Linear motors are the direct linear counterpart of rotary motors. They create linear motion by electromagnetic forces generated in the stator, which interact with the mover (often a slider with magnets), moving it along a path without requiring gears or belts.

Applications: Linear motors are used for tasks that require fast and accurate linear movement over longer distances. They are essential in industrial automation for assembly lines and transport systems, and in CNC machines and robotics for precise and repetitive actions.

Advantages: High speed, high precision, high force, long travel range.

Disadvantages: Large, heavy.

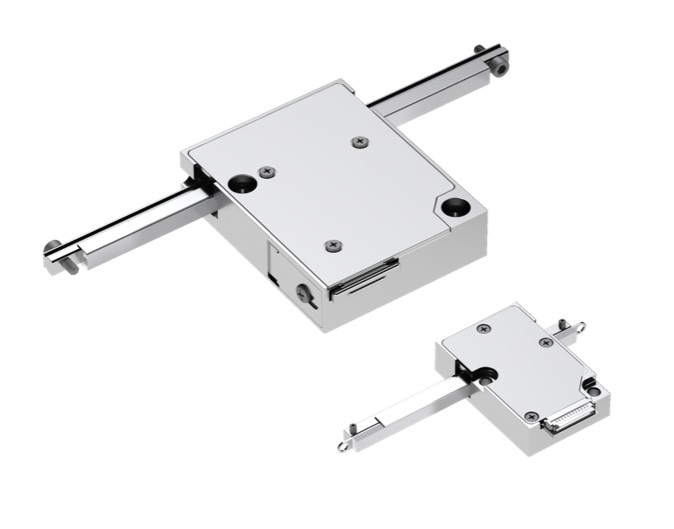

Ultrasonic piezo actuators

Working principle: Utilizes elliptical oscillations of the contact points to generate motion. This advanced method allows for high-speed, precise movement with minimal noise.

Applications: The ultrasonic piezo actuator is perfect for medical, semicon, and laboratory environments where precision, small size, and a large travel range are essential. Its high speed, low voltage and noiseless operation are beneficial in many applications.

Advantages: Very compact, high speed, high precision, unlimited travel range, very long lifetime, integrated controller, noiseless, low cost compared to linear motors and voice coil actuators, self-locking, low power consumption, low voltage, no wear-induced play.

Disadvantages: Not suitable for high-force applications.

Comparative overview: Voice coil actuators vs Linear motors vs Ultrasonic piezo actuators

| Type | Size | Speed | Force | Resolution | Travel Range | Lifetime | Noise | Power Consumption | Internal Voltage | Price |

|---|---|---|---|---|---|---|---|---|---|---|

| Voice coil actuator | Bulky, wide | > 1 m/s | < 5 N | High | < 10 mm | Moderate | Low | Moderate | Low - medium | High (< €500) |

| Linear motor | Bulky, long | > 5 m/s | > 10 N | High | > 100 mm | Good | Silent | High | Medium (> 60 V) | High (< €500) |

| Ultrasonic piezo | Compact, slim | > 1 m/s | 1-10 N | High | Unlimited | Very good (> 1000 km) |

Silent | Low (self-locking) | Safety (< 48 V) | Medium (< €250) |

Please note that these are typical values. There may be exceptions.

Conclusion

When comparing voice coil actuators to linear motors, it is only logical to include ultrasonic piezo actuators in the comparison as well.

Whereas voice coil actuators are precise and simple, they are not suitable for applications where stroke length or power is required, where a slim form factor is essential or price plays an important role.

Linear motors, on the other hand, offer more force and travel range compared to voice coil actuators. However, they are bulky and heavy, making them unsuitable for applications where space and mass are limiting factors.

Lastly, ultrasonic piezo actuators stand out for their all-round performance and versatility. They offer high speed, travel range and precision in a compact, efficient and extremely durable design. Compared to voice coil actuators, they are much more suitable for most applications. Compared to linear motors, they offer less force, but are superior in most other aspects while being less costly.

Take a look at our XLA ultrasonic piezo actuator or learn all about piezo technology here.