Failsafe

Piezo shutters and piezo motion systems have a huge advantage in comparison to electromagnetic alternatives: the minimal number of moving parts. In electromechanical motion systems, there is very often a form of transmission, using gears, wormwheels, etc. All of these components are prone to failure and each additional component decreases the MTBF (Mean Time Between Failures).

Lightweight

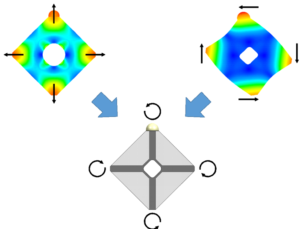

In piezo motion systems, there are only two components: the vibrating piezo element and the moving functional component. This means that the piezo element is pushing directly on the stage, shutter, mirror, etc that needs to be moved. Check this page if you want to learn more on how piezo stages work.

Because of the absence of any metals in the piezo motor, the minimal number of components and the low weight of ceramics, a piezo-driven system is the most lightweight motion solution possible. The basic drive system only weighs a couple of grams and complete stages start at weights of 55g (rotary stage) and 50g (linear stage) . Piezo stages are not dependent on the material choice, as long as sufficient stiffness is present; custom material choices can allow even more weight savings.

Vibration proof

Piezo systems have very few components (check our motor breakdown here). These components are physically connected by the inherent holding force of the system, resulting in a strong vibration robustness. And if any movement should take place, this will not damage the system; the inherent design allows manual override without damaging or affecting the system. For this reason, piezo motors are also used in camera lenses, allowing the photographer to manually override the motion system for initial rough positioning before using the piezo system for fine positioning.

Consumption-free holding force

Energy is scarce in satellites and space systems, so piezo-driven systems are a perfect fit, using only a few watts to move. But even more important: when the desired position is reached, the system stabilises at this position without any energy consumption. This is due to the mechanical tension between the motor and the driven element, resulting in a holding force of 1–5 Newtons. This also means the complete absence of any motor vibration during standstill in the preferred position, giving you the perfect image quality.

Applications

Xeryon precision stages and shutters are suitable for:

- Telescope mirror adjustments

- Antenna positioning

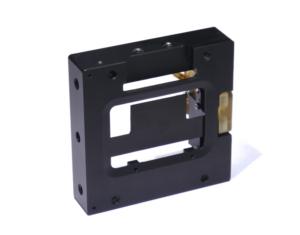

- Satellite camera shutters

- Mirror positioning

- Sample collection and manipulation