Precision linear stages | Miniature

Compact precision linear stages with ultrasonic piezo technology. High speed & high precision in a miniature format. Easy to install, easy to operate.

Lead time just 1 - 2 weeks for most products. Evaluation kits available for all of our products.

Linear piezo stages

Xeryon offers a range of precision linear stages in different lengths and with many additional options. With travel ranges up to 100 mm, the number of possible applications with these miniature linear stages is endless. Thanks to the patented Crossfixx™ ultrasonic piezo technology, travel velocities of 200 mm/s can be reached, making Xeryon's linear piezo stages the fastest precision stages on the market. Our miniature linear stages are perfectly fit for scanning setups, providing constant scanning speed with a speed stability of less than 2%.

All of our stages are easy to install and intuitive to use. Connect the stage to the controller and move to the desired position by using our software or by guiding with our separate manual controls.

Xeryon's precision linear stages offer different levels of precision, from a resolution of 1.25 µm, up to a resolution of 1 nm. For each model, additional options are available – for example, high vacuum compatibility, making our linear stages the perfect solution for your SEM or your vacuum chamber. With the optional extra small cage, we can get even more travel distance from our stages, driving the volume-to-stroke ratio to the limit.

Of course, Xeryon precision linear stages also benefit from the same advantages as our rotary stages. Thanks to our Crossfixx™ technology, the stages are self-locking when in position, without any vibrations or energy consumption. The ultrasonic technology prevents the typical unpleasant sounds associated with most piezo motion systems, rendering ours completely silent.

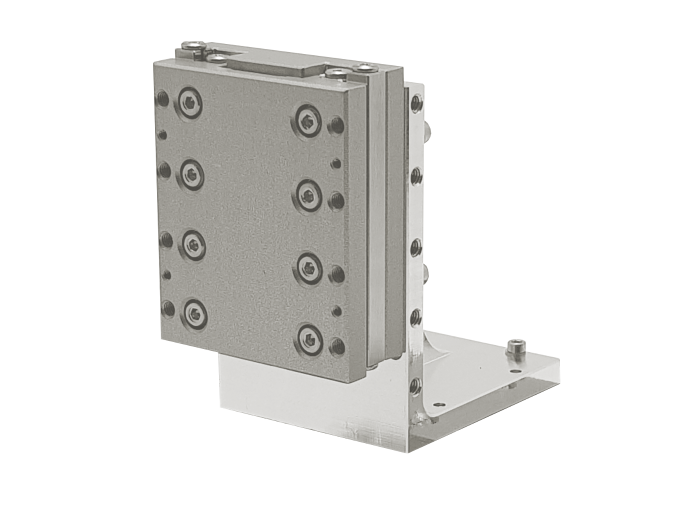

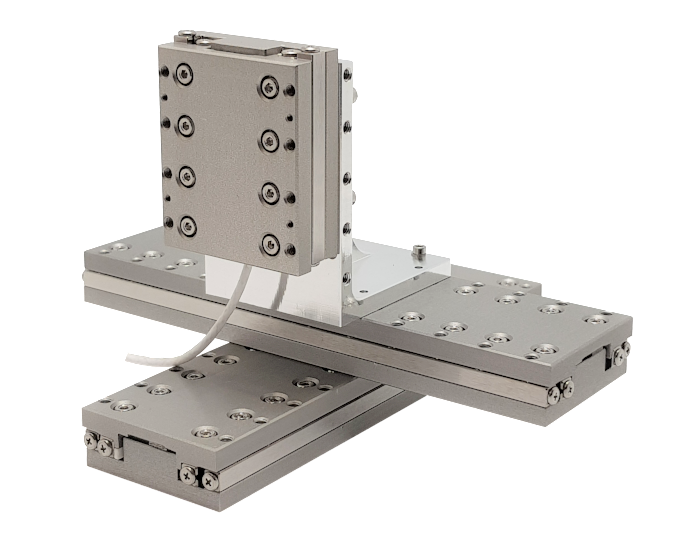

All of our precision stages (rotary and linear) can be combined to create an axes configuration that suits your needs. The stages are easily mountable and custom brackets can be made if needed.

If you can’t find exactly what you need in our standard product range, contact our engineering department for custom linear stages. Check our custom project section for more information.