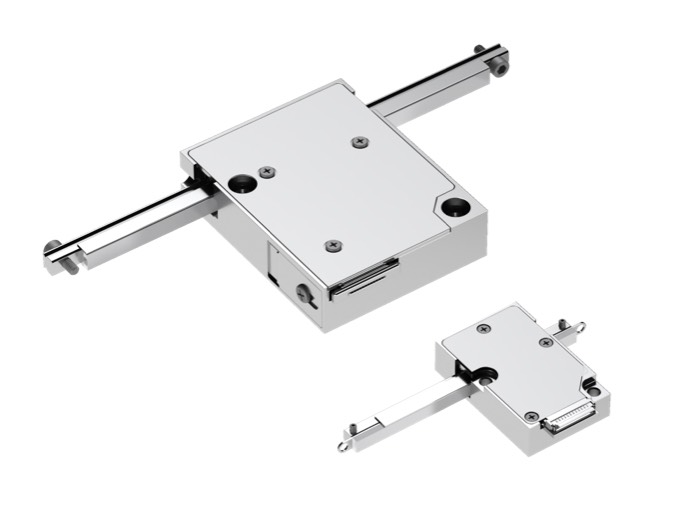

Self-locking linear actuators

Xeryon's expertise in self-locking linear actuators, powered by an ultrasonic motor, offers an innovative solution in motion control. Our micro actuators are unique as they can maintain their position without needing power, providing unmatched stability and energy efficiency compared to traditional actuators.

Gone are the days of worrying about energy consumption or position drift when precisely positioning your lens or semicon manufacturing component.

The self-holding feature is just one of the many aspects of our XLA micro actuators. However, as passive locking can be crucial for certain actuator applications, we decided to highlight this aspect in this article.

The strength of self-locking actuators

Our linear actuators are designed with a friction-based mechanism inherent to our ultrasonic technology. The ultrasonic motor that drives the actuator is spring-loaded against the actuator rod. This allows the actuator to hold its position without any power consumption or drift, offering reliability and complete stability, unmatched by traditional actuators that continuously consume energy to maintain position.

The holding force of these actuators is equal to their driving force. For example, an actuator with a driving force of 5N has a holding force of 5N. This means the actuator can exert the same amount of force to hold its position as it does to move, ensuring consistent performance in both movement and static positions.

This is important for several reasons:

Stability in stationary position: When the actuator is not powered and is holding a position, it can resist an external force of up to 10N without moving (in case of a 10N motor). This self-locking property makes it extremely stable and reliable in its stationary state, which is essential in environments where precision and stable control is vital, such as medical devices and sensitive research environments.

Some electromagnetic actuators will drift slightly when trying to hold a fixed position, meaning there is a loss of precision. With our actuators, the ultrasonic motor is shut off completely when the desired position is reached.

Energy efficiency: Since the actuator doesn't require power to hold its position, it can maintain stability without consuming energy, which is a significant advantage in terms of energy conservation and operational efficiency. This is vital in portable devices, but also for decreasing energy costs in industrial automation, for example.

Simplicity and reliability: The ability to hold with the same force as it drives simplifies the design and increases the reliability of the actuator, as there is no need for additional mechanisms or systems to maintain its position when powered off.

Compact, efficient and built to last

As mentioned, our linear actuators are not only self-locking but also compact, durable, fast, precise and noiseless. Capable of enduring over 1000 kilometers of movement or 20 million cycles, they offer a sustainable, long-lasting option for various needs.

With their ability to provide rapid movement up to 500 mm/s, micrometer accuracy, and varied stroke lengths from 5mm to 300mm, our actuators are a huge leap forward in motion technology.

For further details and full product specifications, please visit our XLA product page.