Vertical piezo stages | XVS

Compact, fast, precise & durable

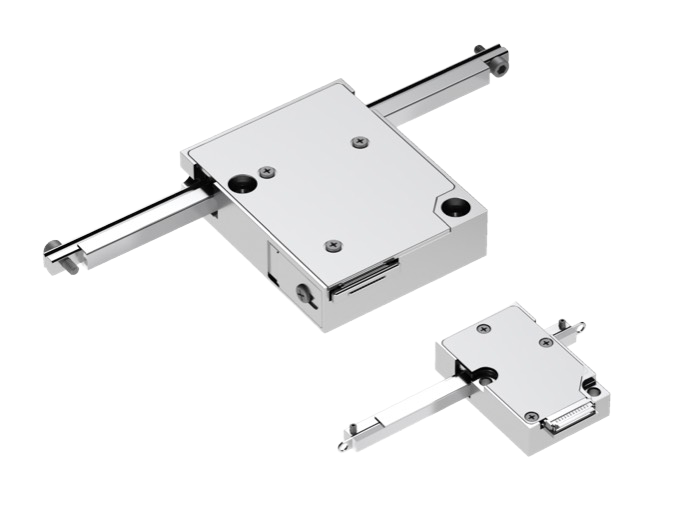

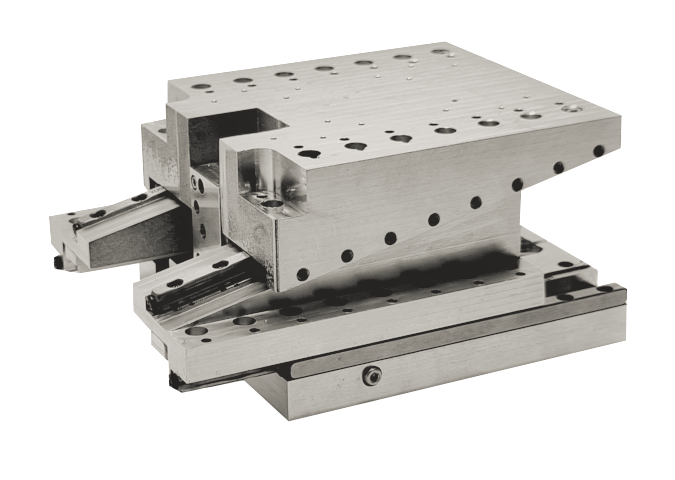

This is the XVS series. These vertical piezo stages offer fast submicron positioning on the vertical axis while keeping size at a minimum.

Additional benefits of the stage's ultrasonic piezo motor include a very long lifetime, quiet operation and power-off locking.

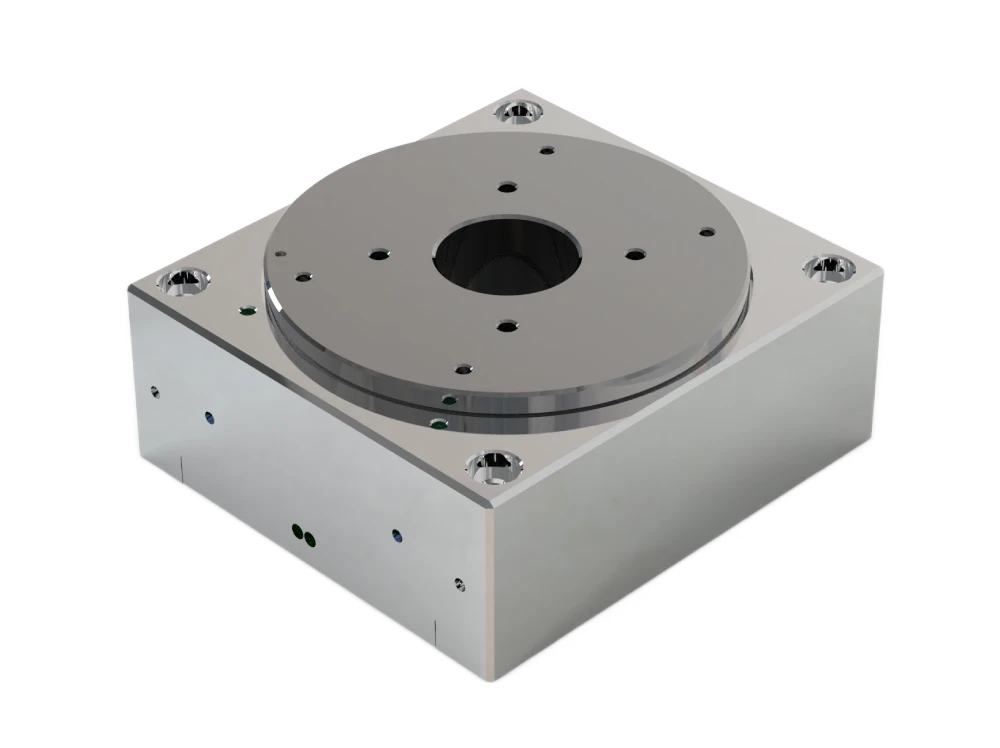

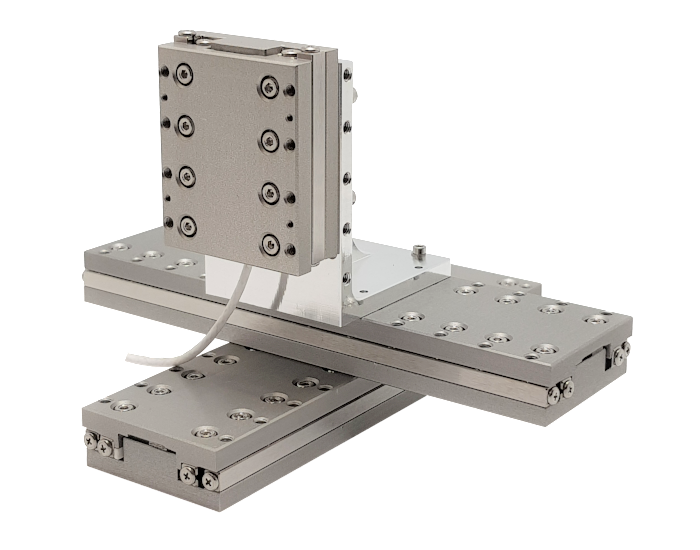

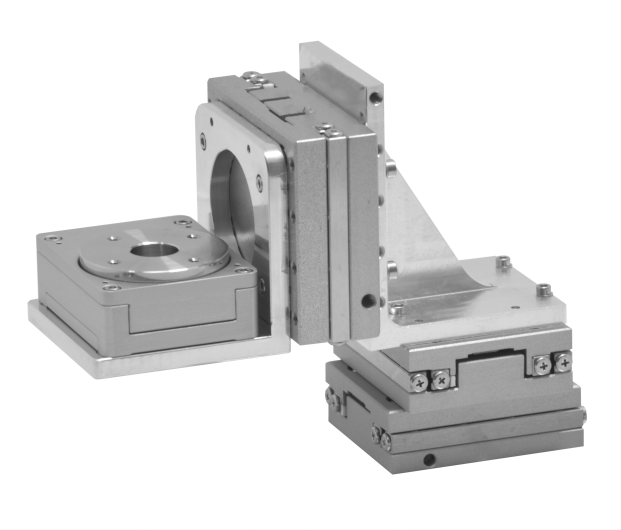

Xeryon's vertical stages can easily be combined into a multi-axis setup (e.g. with horizontal or rotary stages) and are available as non-magnetic and vacuum-compatible versions.

Enjoy!

Only 1 - 2 weeks lead time for most products.

Compact & precise vertical stage

Compact

Starting at a mass of less than 50 grams

Precise

Resolutions between 1.25 µm and 1 nm (open-loop also available)

Fast

Up to 200 mm/s in closed-loop, 1000 mm/s open-loop (minimum: 1 µm/s)

Long travel:

Stroke lengths between 10 and 110 mm

All machining, assembly and quality control done in Belgium, Europe

Large volumes or custom designs? Explore our OEM solutions

Fast point-to-point positioning

Stroke frequency up to 50 Hz

Smooth

1N, 3N and 5N direct-drive ultrasonic piezo motors

Durable

Lifetime > 1000 km or 20 million cycles

Strong

Load capacity up to 100 grams or 500 grams (mass compensation)

Versatile

Non-magnetic and vacuum-compatible versions available

Compatible

One-to-0ne interchangeability with other stage brands

Select your vertical piezo stage

Driving force

*The selected length is only available with a 1N motor

*The selected length is only available with a 3N motor

Stage height

= Travel range

27 - 92 mm

Encoder resolution

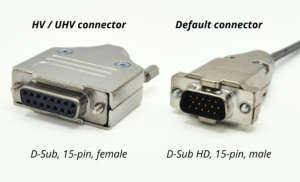

HV / UHV vacuum - optional ⓘ

Short cage - optional ⓘ

Non magnetic - optional ⓘ

= Maximum payload

Product code:

Dimensions:

30 - 120 x 34 x 13 mm

Price indication:

Single axis example: XVS-3-40-1250 + single-axis controller ≈ €2100 / $2300

XYZ setup example: 2x XLS-3-40-1250 (XY) + 1x XVS-3-40-1250 (Z) + three-axis controller ≈ €6500 / $7050

Prices depend on precision level, length, driving force and optional features.

Lead time 1 - 2 weeks for most products. Evaluation kits available.

Need extra lifting capacity? Check out our vertical lifting platform.

Compact, precise & fast vertical stages

-

No wear-induced play (no loss of accuracy over time)

-

Maintenance free

-

No magnetic field generation

-

Direct-drive, no bulky gears or other transmission components

-

Back-driveable (manually overridable without affecting lifetime)

-

Low & safe voltage (<48V)

-

Low power consumption

-

Capable of slow and constant scanning speeds

Technical details

Ultrasonic vertical piezo stage | XLS

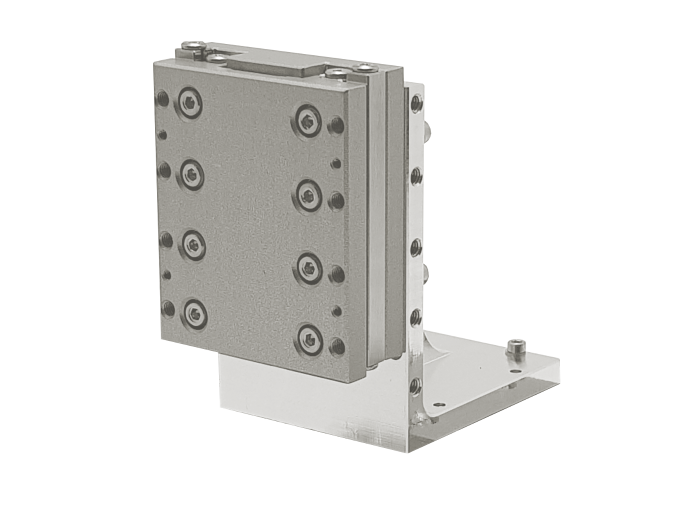

The Xeryon Vertical Stage (XVS) is a precise vertical stage driven by an ultrasonic piezo motor. This allows for fast positioning with submicron precision. The self-locking piezo motor holds the position of the vertical stage when it is not powered. As a result, heat dissipation is considerably reduced.

The XVS is the fastest vertical stage of such a small size in the world.

Not familiar with ultrasonic piezo technology? Have a look at our evaluation kits, the perfect way to experiment with our products!

Not what you're looking for? We also design custom stages for your specific product. Contact us to talk about a custom stage design.

Mass compensation

The Xeryon Vertical Stage can be equiped with a mass compensation spring. The spring compensates a large portion of the weight of the payload, still alowing the piezo-motor to move the stage up and down. What's the catch? The load can't vary too much. For example: if you have a load of 300 grams, it shouldn't vary more than 40g in order to lift it with our 1N motor.

Using a mass compensation mechanism is an elegant way to lift a heavy load with a small lifting stage. You keep the compactness of a piezo-stage, but you get the lifting power of convention drive technology.

Xeryon uses tension springs and magnetic counterweights in its mass compensation designs. Contact us to know more about this clever solution.

Frequently asked questions

Can't find what you're looking for?

Apologies! Send us your question and we will get back to you as soon as possible.