Ultrasonic Piezo Motors: The World's Smallest High-Performance Motion Technology

Breakthrough patented motion technology that redefines compactness, precision, and speed.

Reading time: 5 min

For years, engineers have thought of piezo motors as precise but flawed: slow, very noisy, and limited in travel range. These perceptions came from early designs like stick-slip and walking piezo motors, which struggled with speed, durability, and noise. Even today, these remain the most commonly used piezo motor designs, so the assumption has persisted across the industry.

For years, engineers have thought of piezo motors as precise but flawed: slow, very noisy, and limited in travel range. These perceptions came from early designs like stick-slip and walking piezo motors, which struggled with speed, durability, and noise. Even today, these remain the most commonly used piezo motor designs, so the assumption has persisted across the industry.

But piezo technology has moved on. Today’s ultrasonic piezo motors deliver high-speed nanometer positioning over long travel ranges in a compact footprint. They are also up to 100x more durable than traditional piezo motors. And as a bonus, they operate completely silently, opening doors to new applications.

In this article, we’ll explore how piezo motors work, the strengths and drawbacks of traditional types, and how Xeryon’s ultrasonic piezo is redefining the future of precision motion.

What Are Piezo Motors and How Do They Work?

A piezo motor is a motion device that uses the piezoelectric effect, which is the ability of certain materials (usually ceramics or crystals) to expand or contract when electric voltage is applied or removed. Unlike electromagnetic motors that rely on coils, gears, or magnets, piezo motors generate motion directly from these tiny deformations.

By amplifying this effect through mechanical structures, piezo motors can achieve linear or rotary motion with sub-micrometer to sub-micron accuracy, making them ideal for compact systems where space and precision are critical. Engineers often explore the different types of piezo motors and their working principles to understand which design best suits their needs.

The most common types include:

- Stick-slip (inertia piezo motors)

- How they work: A piezo element slowly expands to make the slider “stick” and move, then contracts rapidly so inertia makes it “slip,” creating tiny stepwise motion.

- Advantages: Simple design, precise at very small steps.

- Disadvantages: Slow, noisy, limited travel due to friction, short lifetime, requires high driving voltage, and prone to resonance effects.

- Walking piezo motors

- How they work: Multiple piezo elements extend and retract in sequence, “walking” a rod forward.

- Advantages: More durable than stick-slip, good precision.

- Disadvantages: Limited travel lengths, relatively slow, complex design.

- Ultrasonic piezo motors

- How they work: Piezo elements vibrate at ultrasonic frequencies, typically tens to hundreds of kilohertz, generating standing or traveling waves along a stator. These vibrations produce continuous frictional contact with a slider or rotor, converting microscopic oscillations into smooth, high-speed linear or rotary motion.

- Advantages: Compact, fast and capable of long strokes with sub-micron or nanometer precision. Much faster and more durable than other types of piezo motors.

- Disadvantages: Typically used in only high-performance, innovative systems where advanced precision, reliability and throughput are critical.

Stick slip piezo motor working principle Walking piezo motor working principle Ultrasonic piezo motor working principle

Unlike traditional piezo technologies, which were often seen as slow or noisy, ultrasonic motor capabilities overcome these drawbacks and represent the next generation of precision motion. As piezo designs continue to evolve, it becomes clear that not all piezo motors are created equal, and understanding their differences is key to unlocking new applications. This is where ultrasonic piezo technology takes center stage.

What is Ultrasonic Piezo?

In ultrasonic piezo technology (also known as resonant piezo), a piezoelectric element is driven at its resonance frequency, typically tens to hundreds of kilohertz (kHz). This is above the range of human hearing, which is why the technology is called ultrasonic piezo.

At these extremely high frequencies, the piezo element’s microscopic expansion and contraction cycles repeat around 100,000 times per second (100 kHz). These vibrations create tiny elliptical movements on the surface of the actuator that drive a slider or rotor through gentle frictional contact. The result is smooth, continuous motion with nanometer precision, high speed, and silent operation, a combination that traditional piezo systems or electromagnetic motors cannot achieve.

Because ultrasonic piezo motors run at very high frequencies (around 100 kHz), the surrounding mechanics cannot react to the vibrations they generate. As a result, they do not transfer noticeable vibration into the system they are built into, such as a sensitive analytical instrument. Electromagnetic motors, on the other hand, often operate at lower frequencies where mechanical resonance can occur, making it more likely that they disturb the surrounding structure.

There are two main types of ultrasonic piezo motors: traveling-wave and standing-wave:

- Traveling-wave motors

In a traveling-wave motor, an ultrasonic wave moves around a circular piezoceramic ring. A contact point rides this wave to create smooth rotary motion, making it ideal for compact systems like camera lenses. Because generating a traveling wave in a linear structure is difficult, this design is mainly used for rotary motion. It can achieve high forces but is generally slower and less durable than standing-wave designs. - Standing-wave motors

Standing-wave motors, such as Xeryon’s CrossFixx™ technology, use one or a few contact points that vibrate in an elliptical trajectory against a slider. This produces precise linear or rotary motion with nanometer accuracy. Operating at ultrasonic frequencies keeps them silent, energy-efficient, and thermally stable, while resonant operation enables high speed (up to 1000 mm/s) and a long lifetime.

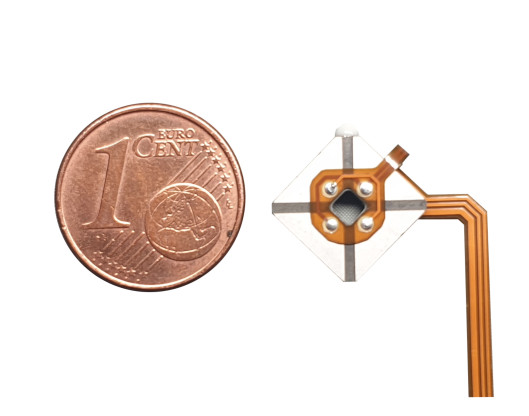

What is Xeryon’s Patented CrossFixx™ Piezo Technology?

Our patented CrossFixx™ ultrasonic motor powers all of Xeryon’s motion products - from linear actuators to rotary stages.

Originally developed by researchers at the University of Leuven (KU Leuven), it offers the core advantages of piezo technology - high precision and compact dimensions - while being up to 100× faster and more durable than traditional piezo motors. Its speed also enables travel ranges far beyond those of typical piezo systems.

This makes CrossFixx™ a superior alternative to many miniature motor technologies on the market today, both piezo and electromagnetic.

How does CrossFixx™ work?

The motor vibrates in two modes that can be activated independently:

- Activate both → up-and-down motion

- Activate one → sideways motion

By combining the two, a precise elliptical movement is generated - perfect for pushing a rod or rotor with nanometer precision.

The elliptical motion minimizes surface contact, making the CrossFixx™ motor last hundreds of times longer than stick-slip piezo systems, which rely on constant friction and slippage.

The motor is driven at its resonance frequency, typically around 100 kHz, causing the vibration cycle to repeat approximately 100,000 times per second. Operating at this frequency enables both high positioning speed and high precision, while remaining quiet to the human ear and functioning at relatively low voltages.

For the detailed working principle, please see the article on our CrossFixx™ ultrasonic piezo motor.

CrossFixx™ vs. Traditional Piezo vs. Electromagnetic

The table below highlights the differences between the Xeryon CrossFixx™ ultrasonic piezo motor, traditional piezo motors, and electromagnetic drives (both direct-drive and linear-to-rotary).

| Characteristics | Xeryon CrossFixx™ | Traditional Piezo | EM - Direct-Drive | EM - Stepper + Screw |

|---|---|---|---|---|

| Compact | ✔ Yes | ✔ Yes | ✖ No | ✖ No |

| Lightweight | ✔ Yes | ✔ Yes | ✖ No | ✖ No |

| Backlash-Free | ✔ Yes | ✔ Yes | ✔ Yes | ✖ No |

| Self-Locking | ✔ Yes | ✔ Yes | ✖ No | ✔ Yes |

| Low Heat | ✔ Yes | ✔ Yes | ✖ No | ✖ No |

| No Magnetic Field | ✔ Yes | ✔ Yes | ✖ No | ✖ No |

| Vaccum Compatible | ✔ Yes | ✔ Yes | ✖ No | ✖ No |

| Fast | ✔ Yes | ✖ No | ✔ Yes | ✖ No |

| Long Stroke | ✔ Yes | ✖ No | ✔ Yes | ✔ Yes |

| Durability | ✔ Yes | ✖ No | ✔ Yes | ✔ Yes |

| Low Voltage | ✔ Yes | ✖ No | ✔ Yes | ✔ Yes |

In short, CrossFixx™ combines the compactness and precision of traditional piezo systems with the high speeds, long travel ranges, and durability typically associated with electromagnetic direct-drive technologies such as linear motors and voice coils. Unlike direct-drive systems, however, CrossFixx™ does not require continuous power to maintain its position. In addition, it operates at lower voltages than many conventional piezo motors, which supports higher energy efficiency, enables smaller controller electronics, and simplifies integration into OEM systems.

How Ultrasonic Piezo is Revolutionizing The Motion Industry

Ultrasonic piezo technology is not just improving motion control; it is replacing long-standing actuator architectures that have constrained system design for decades. Traditional solutions depend on gears, screws, coils, or slow high-voltage piezos that add bulk, limit speed, and consume energy even when not moving. Ultrasonic piezo motors, by contrast, use resonance-based motion to generate continuous movement without these mechanical or electrical penalties. The result is a class of actuators that deliver order-of-magnitude gains in speed, precision, and efficiency in a form factor that is significantly smaller than conventional alternatives, including their drive electronics.

What makes ultrasonic piezo transformative is the engineering freedom it unlocks. Systems that once required multiple stages, gear trains, or complex feedback loops can now be built around a single, self-locking actuator that maintains position with virtually no power. Motion can be embedded directly inside optical systems, medical devices, semiconductor instruments, and metrology platforms, even in environments where electromagnetic motors are unsuitable because of magnetic fields, vibration, or thermal sensitivity. Designs that were impractical or physically impossible with electromagnetic or classical piezo mechanisms are now achievable.

This shift is already enabling a new generation of instruments across photonics, life sciences, semiconductor inspection, metrology, and ultra-compact robotics. As industries move toward smaller, faster, and more automated systems, ultrasonic piezo actuators are emerging not as an incremental improvement but as a foundational motion technology that removes legacy constraints and creates opportunities for breakthroughs in performance, reliability, and device architecture.

Applications of Xeryon's Motion Products

Automated Imaging & Microscopy: Piezoelectric motors have long been used in microscopy for high-precision focusing, especially along the vertical axis. However, they traditionally suffer from:

- limited travel range

- slow speeds

- bulky external controllers

Electromagnetic motors offer an alternative but require continuous power to hold position and take up (much) more space. Ultrasonic piezo solves these issues by providing fast, nanometer-accurate movement over centimeter-scale travel ranges in a compact package. This opens the door to faster and more precise automated imaging, including both objective focusing and sample positioning.

Semiconductor Manufacturing: This industry is familiar with piezo technology, although it is typically used only for small, low-duty fine adjustments.

Xeryon’s CrossFixx ultrasonic motors take piezo precision and extend it to 24/7 industrial duty cycles. They deliver:

- piezo-class accuracy

- the speed and durability associated with electromagnetic motors

- a dramatically reduced footprint

This allows engineers to design smaller and more capable machines, an important advantage in a world where miniaturization and high throughput are essential.

Medical Devices and Life Science Instrumentation: Turning scientific breakthroughs into real-world impact requires compact, reliable, and fast tools. Ultrasonic piezo technology supports this by enabling:

- faster analytical instruments

- more precise surgical robots

- smaller benchtop equipment

- high-throughput lab automation

- more compact handheld devices

When a robot is not accurate enough, an instrument is not fast enough, or a device is too large, Xeryon’s ultrasonic motors remove those limitations and help engineers create better tools for clinicians, researchers, and patients.

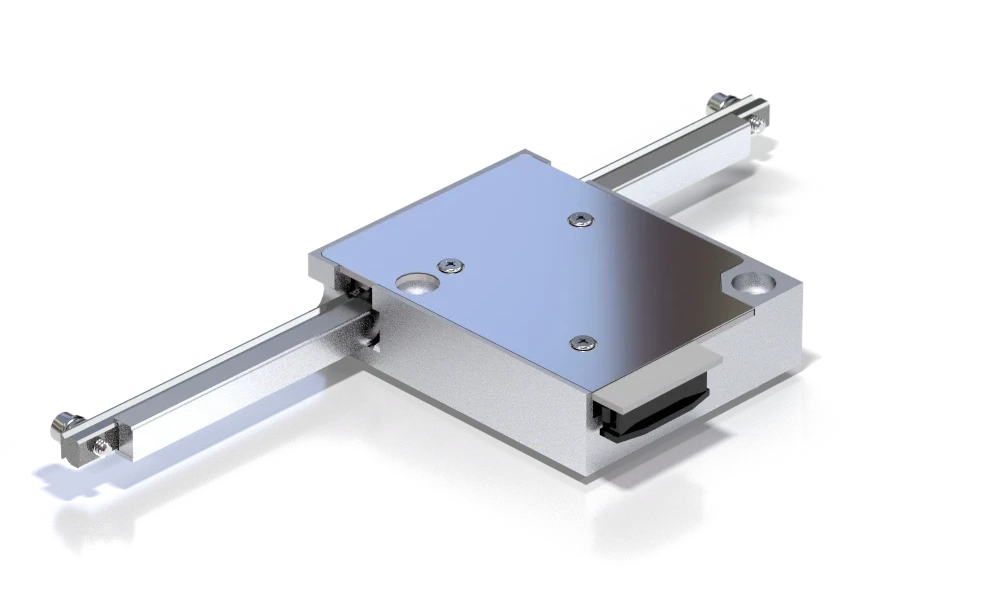

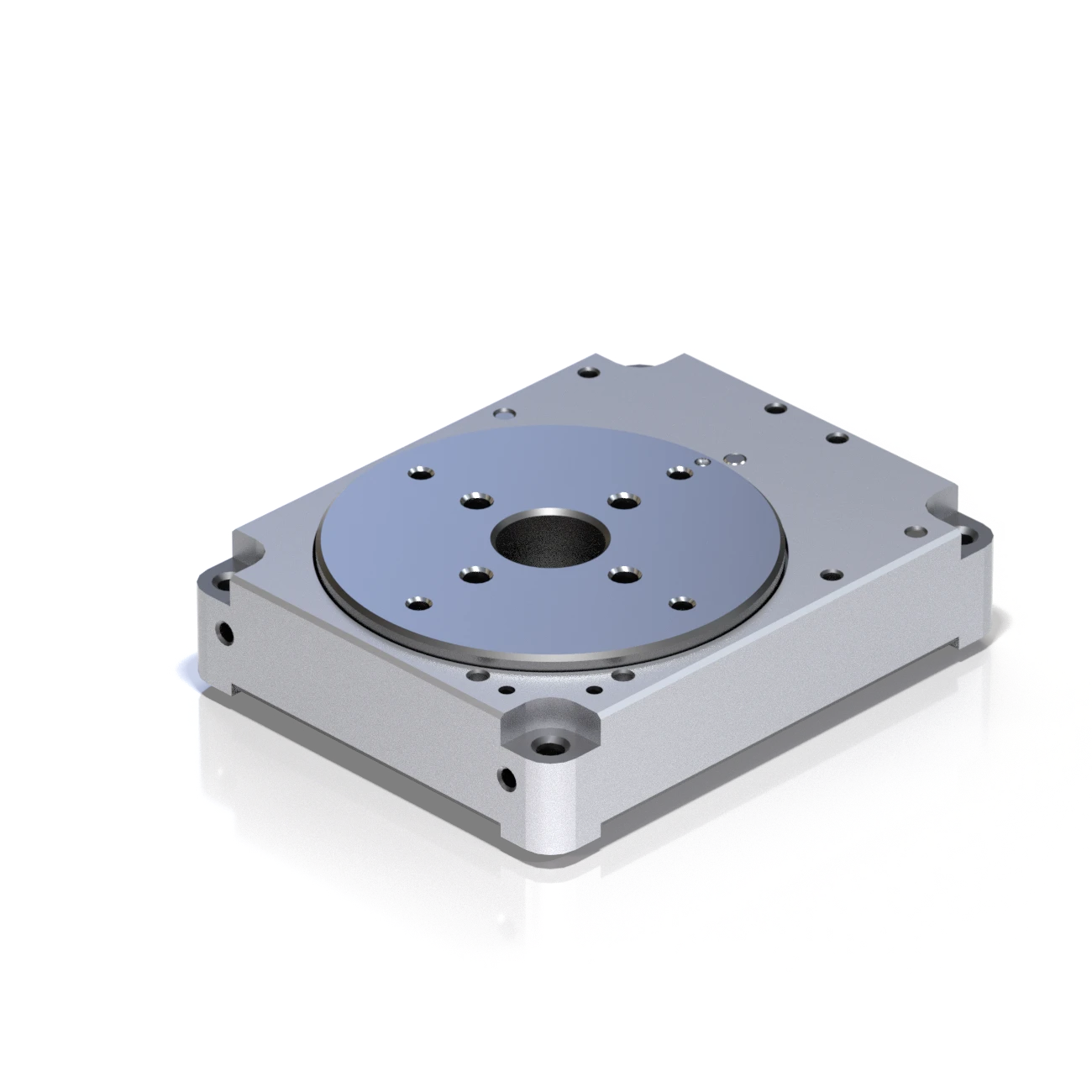

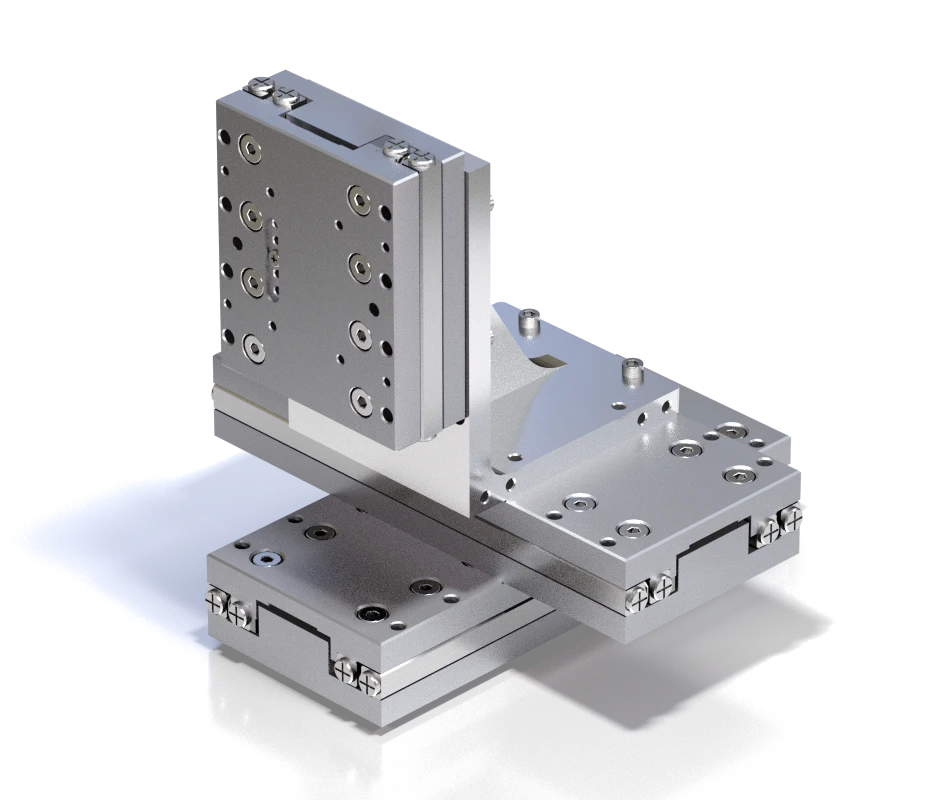

Xeryon's Actuators & Stages

Ultrasonic piezo technology sits at the core of Xeryon’s complete motion portfolio, enabling compact, high-performance systems used in precision instruments worldwide.

Conclusion

Ultrasonic piezo technology is redefining what motion systems can achieve, combining compact size, high stability, and exceptional performance in ways that traditional actuators cannot. As industries demand faster, smaller, and more precise motion solutions, ultrasonic piezo motors are becoming a key enabling technology across optics, life sciences, semiconductor tools, and advanced automation.

Whether you're designing a new instrument or upgrading an existing system, Xeryon’s ultrasonic piezo products offer a modern, reliable foundation for next-generation motion.

Explore our product range, access datasheets, or reach out to our team to discover how ultrasonic piezo technology can accelerate your innovation.